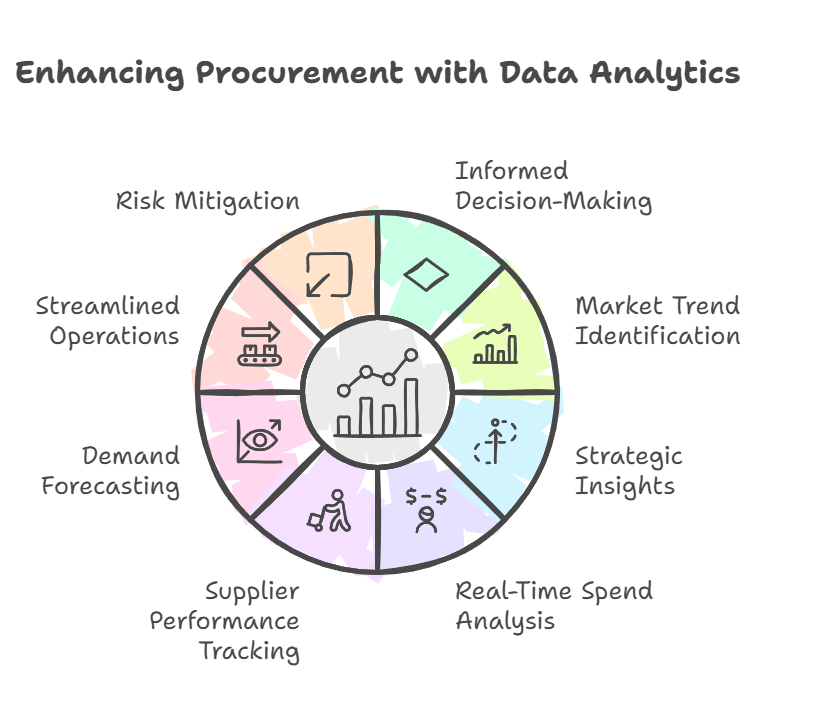

In today's business landscape, procurement data holds immense value for corporations. Leveraging data analytics in procurement empowers teams to make informed decisions, identify market trends, and unlock strategic insights. This wealth of information enables organisations to optimise their purchasing strategies and drive performance across the supply chain.

By harnessing the power of procurement data, companies can gain a competitive edge. Advanced analytics tools provide real-time spend analysis, supplier performance tracking, and demand forecasting. These capabilities allow procurement teams to streamline operations, mitigate risks, and uncover new opportunities for cost savings and value creation.

Key Takeaways

- Data-driven procurement enhances decision-making and strategic optimisation

- Advanced analytics tools provide real-time insights for spend analysis and supplier management

- Leveraging procurement data drives performance and creates value across the supply chain

Understanding Procurement in Modern Enterprises

Procurement in today's enterprises plays a vital role in value creation and governance. It has undergone significant changes due to digital transformation and advanced analytics. These shifts have enhanced transparency and efficiency in purchasing processes.

Defining Strategic Procurement

Strategic procurement focuses on long-term value creation for organisations. It involves careful planning and analysis of spending patterns. Procurement teams work to align purchasing decisions with company goals.

Key elements of strategic procurement include:

• Supplier relationship management

• Risk mitigation

• Cost optimisation

• Innovation sourcing

Advanced analytics help procurement professionals make data-driven decisions. They can identify cost-saving opportunities and improve supplier performance. This approach boosts the company's competitive advantage.

The Evolution of Procurement

Procurement has transformed from a tactical function to a strategic one. In the past, it focused mainly on getting the lowest prices. Now, it's about creating value across the supply chain.

Digital tools have revolutionised procurement processes. They enable:

• Real-time data analysis

• Automated purchase orders

• E-sourcing platforms

• Supplier performance tracking

Procurement market intelligence has become crucial. It helps companies adapt to changing market conditions. AI and machine learning are now being used to predict supply chain disruptions and optimise inventory levels.

Transparency has improved significantly. Stakeholders can now track spending and supplier performance easily. This has led to better governance and reduced risks in procurement operations.

Procurement Teams and Roles

Procurement teams play a vital role in organisations. They manage spending, select suppliers, and negotiate contracts. These teams need diverse skills to handle complex tasks and drive value.

Core Functions of Procurement Teams

Procurement teams have several key responsibilities. They analyse spending patterns to find cost-saving opportunities. They also research and evaluate suppliers to ensure quality and reliability.

Contract negotiation is another crucial task. Teams work to secure favourable terms and prices. They must balance cost savings with maintaining good supplier relationships.

Risk management is increasingly important. Teams assess potential supply chain disruptions and develop mitigation strategies.

Procurement professionals also focus on process improvement and efficiency. They look for ways to streamline operations and reduce waste.

Collaboration with other departments is essential. Procurement teams work closely with finance, legal, and operations to align goals and strategies.

Developing Skills within Procurement Professionals

Procurement roles require a mix of technical and soft skills. Data analysis is becoming more critical. Professionals need to understand procurement analytics tools to make informed decisions.

Negotiation skills are fundamental. Training in this area can help secure better deals and maintain positive supplier relations.

Technology proficiency is vital. Teams must be comfortable with e-procurement systems and other digital tools.

Sustainability knowledge is growing in importance. Professionals need to understand eco-friendly practices and regulations.

Leadership and communication skills are crucial for senior roles. These help in managing teams and presenting to executives.

Continuous learning is key. Many organisations offer training programmes to keep skills up-to-date.

Digital Procurement and Technological Integration

New technologies are reshaping procurement practices. These innovations boost efficiency, cut costs, and give companies an edge. They change how firms buy goods and handle suppliers.

Artificial Intelligence and Machine Learning

AI and machine learning help firms make smarter choices in procurement. These tools look at loads of data to spot trends and risks. They can guess future prices and demand.

AI helps pick the best suppliers. It checks their past work and financial health. This cuts the risk of supply chain issues.

Machine learning makes buying faster. It can fill in forms and match invoices. This frees up staff to work on bigger tasks.

Digital procurement strategies using AI boost savings. They find new ways to cut costs that humans might miss.

Adoption of Automation and Generative AI

Automation speeds up routine tasks in procurement. It can place orders, track shipments, and pay bills. This cuts errors and saves time.

Generative AI is a new tool in this field. It can write contracts and reports. It also helps create custom product specs.

These tools make procurement more precise. They cut the need for manual data entry. This means fewer mistakes and more time for strategy.

Procurement teams using these tools work faster. They can handle more suppliers and deals at once.

ERP Systems and Advanced Analytics

ERP systems link all parts of a business. In procurement, they track orders, stock, and spending. This gives a clear view of the whole process.

Advanced analytics use this data to find insights. They show where money is spent and how to save more. They can flag high-risk suppliers or spot chances to bulk buy.

These tools help firms plan better. They can see what they'll need to buy in the future. This helps avoid shortages and overstocking.

Data-driven procurement leads to smarter choices. It helps companies get the best value from their spending.

Data Analytics and Insights

Data analytics transforms raw procurement data into valuable insights. It helps companies make better decisions, forecast demand, and optimise spending.

Importance of Quality Data

Quality data is crucial for effective procurement analytics. Clean, accurate data leads to reliable insights and better decision-making. Companies need to ensure their data is complete, consistent, and up-to-date.

Data analytics in procurement relies on various sources, including purchase orders, invoices, and supplier information. Organisations should invest in data cleansing and validation processes to maintain high data quality.

Good data governance practices are essential. This includes setting data standards, defining roles and responsibilities, and implementing data security measures.

Spend Analysis and Visibility

Spend analysis is a key application of procurement analytics. It provides visibility into an organisation's spending patterns and helps identify cost-saving opportunities.

Procurement professionals can gain deep insights into their spending through advanced analytics tools. These tools can categorise spend data, identify maverick spending, and highlight areas for supplier consolidation.

Spend visibility enables:

- Identification of cost-saving opportunities

- Improved supplier negotiations

- Better contract compliance

- Strategic sourcing decisions

Making Data-Driven Decisions

Data-driven decision-making is at the heart of modern procurement. Analytics tools provide actionable insights that guide procurement strategies and tactics.

Predictive analytics can forecast demand, helping organisations optimise inventory levels and reduce costs. It can also predict supplier performance, enabling proactive risk management.

Big data analytics can process vast amounts of structured and unstructured data. This allows procurement teams to uncover hidden patterns and trends that inform strategic decisions.

By leveraging data analytics, procurement teams can:

- Improve supplier selection and performance management

- Optimise pricing strategies

- Enhance risk management

- Drive continuous improvement in procurement processes

Driving Procurement Performance

Procurement performance hinges on data-driven insights and strategic actions. Companies can boost their procurement outcomes through targeted efforts in key areas.

Setting and Tracking KPIs

Key performance indicators (KPIs) are vital for measuring procurement success. Effective KPIs might include:

• Cost savings percentage

• Supplier delivery accuracy

• Procurement cycle time

Organisations should set realistic yet ambitious targets for each KPI. Regular tracking and analysis help identify trends and areas for improvement.

Data visualisation tools can make KPI monitoring more accessible. Dashboards offer real-time insights, allowing procurement teams to spot issues quickly.

Supplier Performance and Relationships

Strong supplier relationships are crucial for procurement success. Regular performance evaluations help maintain high standards.

Criteria for supplier assessments may include:

• Quality of goods or services

• On-time delivery rates

• Pricing competitiveness

• Responsiveness to queries

Feedback sessions with suppliers can foster open communication. This dialogue often leads to mutual improvements and innovation.

Risk management is also key. Diversifying the supplier base can mitigate supply chain disruptions.

Operational Efficiency and Optimisation

Streamlining procurement processes boosts efficiency and reduces costs. Automation of routine tasks frees up staff for strategic work.

E-procurement systems can significantly speed up purchasing cycles. They also improve data accuracy and transparency.

Cost optimisation strategies might include:

• Bulk purchasing discounts

• Standardisation of frequently bought items

• Regular market analysis for competitive pricing

Continuous improvement is essential. Regular audits of procurement processes can reveal bottlenecks and inefficiencies.

Supply Chain Management and Risks

Supply chain management faces numerous challenges in today's complex business environment. Companies must navigate disruptions, adapt to market trends, and assess supplier risks to maintain resilience and efficiency.

Navigating Supply Chain Disruptions

Supply chain disruptions can severely impact business operations. Natural disasters, transportation issues, and sudden demand changes often cause these disruptions.

To mitigate risks, firms implement robust contingency plans. These may include:

• Diversifying supplier networks

• Building buffer inventory

• Developing alternative logistics routes

Organisations also leverage technology to enhance visibility across the supply chain. Real-time data and analytics help predict and respond to disruptions more effectively.

Market Trends and Geopolitical Influences

Market trends and geopolitical tensions significantly shape supply chain strategies. Volatility in global markets can affect raw material costs and availability.

Trade policies and international relations impact supply routes and sourcing decisions. Companies must stay informed about:

• Shifting trade agreements

• Emerging markets

• Political stability in key regions

Adapting to these factors requires agility and foresight. Firms often conduct scenario planning to prepare for various geopolitical outcomes.

Supplier Risk Assessment

Assessing supplier risks is crucial for maintaining a stable supply base. Companies evaluate suppliers based on financial health, operational capability, and compliance standards.

Key areas of focus include:

• Financial stability

• Quality control measures

• Environmental and social governance

Regular audits and performance reviews help identify potential issues early. Many organisations use risk scoring models to quantify and compare supplier risks.

Data-driven insights enable better decision-making in supplier selection and management. This approach helps build a more resilient and reliable supply chain.

Sustainability and Ethical Sourcing

Sustainable procurement practices are reshaping corporate strategies. Companies now prioritise environmental and social impacts alongside financial factors when making sourcing decisions.

Achieving Sustainability Goals

Many firms have set ambitious sustainability targets. Over 70% of companies now view delivering on sustainability goals as a top procurement driver. This shift reflects growing stakeholder pressure and regulatory requirements.

Procurement teams play a key role in meeting these objectives. They evaluate suppliers based on environmental and social criteria. This includes assessing carbon footprints, water usage, and labour practices.

Data-driven approaches help track progress. Companies use sustainability metrics to measure supplier performance. They also analyse spend data to identify areas for improvement.

Sourcing for Value beyond Cost

Ethical sourcing creates value in multiple ways. It helps firms manage risks, enhance reputation, and drive innovation.

Sustainable procurement practices can boost brand value by 15-30%. This shows that customers value companies with strong ethical standards.

Suppliers are also stepping up. Many now offer eco-friendly products and services. This gives buyers more options to meet sustainability goals.

Collaboration is crucial. Buyers and suppliers work together to find sustainable solutions. This can lead to new product designs or more efficient processes.

Governance, Compliance, and Transparency

Good governance, strict compliance, and full transparency form the backbone of effective procurement practices. These elements ensure ethical operations and build trust with stakeholders.

Maintaining Compliance Standards

Corporations must adhere to strict compliance standards in their procurement processes. This includes following all relevant laws and regulations. Companies should create clear policies and procedures for staff to follow.

Regular audits help spot issues early. Data analytics can enhance transparency in procurement. It allows firms to track spending patterns and flag unusual activity.

Staff training is crucial. All employees involved in procurement should understand compliance rules. This reduces the risk of mistakes or misconduct.

Firms should also vet suppliers carefully. This helps ensure they meet ethical and legal standards. A supplier code of conduct can set clear expectations.

Promoting Transparency in Procurement Processes

Transparency in procurement builds trust with stakeholders. It shows the company is acting ethically and responsibly.

E-procurement systems can boost transparency. These platforms create a clear record of all transactions. They make it easy to track and review procurement decisions.

Open communication is key. Companies should share information about their procurement processes. This might include publishing tender details or supplier selection criteria.

Regular reporting helps keep stakeholders informed. Reports should cover key metrics like spending and supplier diversity. They should also highlight any issues or improvements.

Feedback mechanisms allow suppliers and staff to raise concerns. This can help spot problems early and improve processes.

Strategic Partnerships and Collaboration

Strong supplier relationships and joint innovation efforts are key to modern procurement success. Companies that collaborate closely with suppliers gain competitive advantages and drive business growth.

Leveraging Supplier Partnerships

Strategic supplier collaboration transforms procurement from a cost-cutting function to a value-creating engine. Leading firms build deep, long-term partnerships with key suppliers.

These partnerships allow for:

• Shared business planning

• Joint product development

• Streamlined processes

• Risk mitigation

• Enhanced supply chain visibility

Close collaboration enables both parties to identify new opportunities. It also helps address challenges more effectively.

Successful partnerships require trust, open communication and aligned objectives. Regular meetings and performance reviews strengthen relationships over time.

Fostering Innovation through Collaboration

Supplier collaboration fuels innovation by tapping into external expertise and capabilities. Innovative firms actively engage suppliers in their R&D and product development processes.

Joint innovation initiatives may include:

• Co-creation workshops

• Supplier innovation portals

• Shared research projects

• Technology transfer programmes

These efforts help companies access cutting-edge technologies and fresh ideas. They also speed up time-to-market for new products and services.

To foster a culture of collaborative innovation, firms must:

• Provide incentives for suppliers to innovate

• Share relevant data and market insights

• Establish clear intellectual property agreements

• Celebrate joint successes

Category and Demand Management

Category and demand management are key aspects of procurement that help businesses optimise spending and meet customer needs. These strategies allow companies to make smarter purchasing decisions and anticipate future requirements.

Category Management Strategies

Category management involves grouping similar products or services to improve purchasing efficiency. It aims to maximise value across the supply chain. Effective category management strategies include:

• Supplier consolidation

• Standardisation of specifications

• Volume leverage

• Total cost of ownership analysis

By implementing these strategies, organisations can reduce costs and enhance supplier relationships. Category managers use data analytics to identify trends and opportunities within each category. This approach enables them to make informed decisions about sourcing, negotiation, and risk management.

Understanding and Forecasting Demand Patterns

Accurate demand forecasting is crucial for efficient procurement. It helps companies avoid overstocking or stockouts. Advanced analytics tools can analyse historical data, market trends, and external factors to predict future demand patterns.

Key elements of demand forecasting include:

• Historical sales data analysis

• Seasonality and trend identification

• Market intelligence integration

• Collaborative planning with suppliers

By understanding demand patterns, businesses can optimise inventory levels and improve cash flow. This knowledge also supports better negotiations with suppliers and more accurate budgeting.

Frequently Asked Questions

Data analytics plays a crucial role in modern procurement processes. Companies use various methods to analyse spending, track activities, and optimise costs. The job market for procurement analytics professionals has also seen significant changes.

How can data analytics be applied within the procurement process?

Data analytics helps improve decision-making in procurement. It allows companies to analyse spending patterns and identify cost-saving opportunities. Analytics can also forecast demand, evaluate supplier performance, and streamline processes.

Companies use data to negotiate better contracts with suppliers. They can spot trends and risks in the supply chain. This leads to more strategic sourcing decisions.

What methods are commonly employed in analysing procurement data?

Descriptive analytics looks at past performance. It shows what happened in procurement activities. Predictive analytics forecasts future trends based on historical data.

Prescriptive analytics suggests actions to improve outcomes. Machine learning algorithms can spot patterns humans might miss. Data visualisation tools help present complex information in an easy-to-understand format.

What approaches are effective for tracking procurement activities?

Key performance indicators (KPIs) are vital for tracking procurement. Common KPIs include cost savings, supplier lead times, and contract compliance rates.

Real-time dashboards give instant visibility into procurement activities. Spend analysis tools categorise and track expenses across the organisation. Supplier scorecards measure vendor performance over time.

In what ways can procurement spend be analysed to optimise cost savings?

Category management groups similar purchases to find savings. Spend analysis breaks down costs by supplier, department, and product type.

Price benchmarking compares costs against market rates. Analysing payment terms can improve cash flow. Identifying maverick spend helps enforce purchasing policies.

What are the emerging trends in procurement analytics for large companies?

Artificial intelligence is automating routine procurement tasks. Predictive analytics helps companies anticipate supply chain disruptions.

Blockchain technology improves traceability in the supply chain. Cloud-based procurement platforms enable better collaboration with suppliers. Sustainability analytics track environmental impact of purchases.

How has the job market for procurement analytics professionals evolved in recent years?

Demand for procurement analysts with data skills has grown. Companies seek professionals who can interpret complex data sets and provide actionable insights.

Knowledge of advanced analytics tools is now essential. Soft skills like communication and problem-solving are equally important. Many companies offer training to upskill existing procurement staff in analytics.