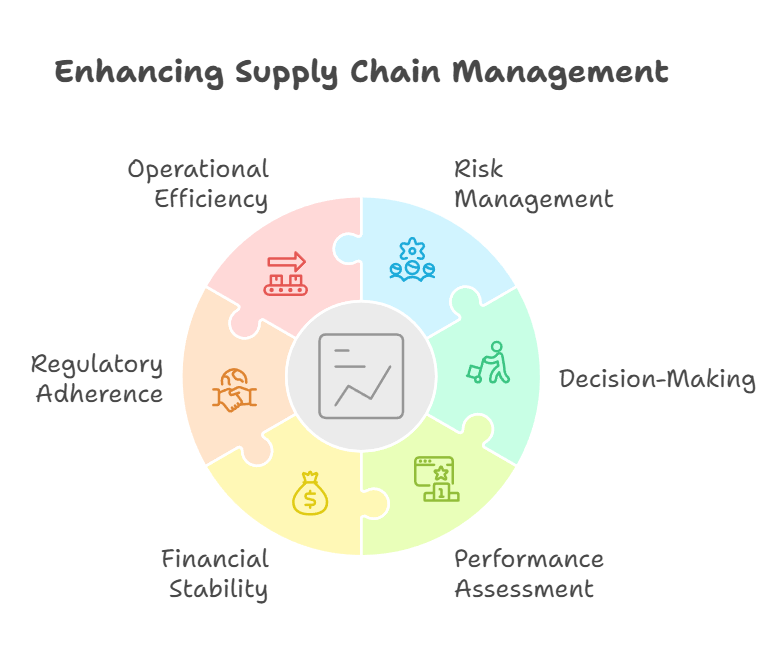

Supplier compliance analytics has become a crucial tool for businesses seeking to manage risks and ensure ethical practices in their supply chains. By leveraging data and advanced technologies, companies can gain valuable insights into their suppliers' performance, regulatory adherence, and potential risks. Supplier compliance analytics helps organisations make informed decisions, mitigate risks, and foster stronger relationships with their suppliers.

These analytics tools examine various aspects of supplier performance, including financial stability, quality control, delivery times, and adherence to environmental and social standards. By analysing this data, businesses can identify potential issues before they become major problems, allowing for proactive decision-making and risk management.

The use of supplier compliance analytics is particularly important in today's complex global supply chains. With suppliers often spread across different countries and regulatory environments, having a comprehensive view of compliance and performance is essential for maintaining operational efficiency and protecting brand reputation.

Key Takeaways

- Supplier compliance analytics improves risk management and decision-making in supply chains

- Data-driven insights help identify potential issues before they become major problems

- Analytics tools assess various aspects of supplier performance, including financial stability and regulatory adherence

Understanding Supplier Compliance

Supplier compliance is crucial for businesses to manage risks and ensure quality. It involves adhering to standards and regulations throughout the supply chain.

Definition and Importance

Supplier compliance refers to suppliers following set standards, rules, and contract terms. This covers performance, environmental rules, and ethical practices.

It's vital for several reasons:

• Ensures product quality and safety

• Protects businesses from legal issues

• Builds trust with customers

• Reduces supply chain risks

Proper compliance helps firms avoid costly recalls and reputation damage. It also supports smooth operations and timely deliveries.

Key Components

Effective supplier compliance has several important parts:

- Risk assessment: Identify potential issues in the supply chain.

- Clear policies: Set out rules and expectations for suppliers.

- Regular audits: Check suppliers' practices and performance.

- Training: Help suppliers understand and meet requirements.

- Corrective actions: Address any compliance gaps quickly.

- Monitoring and reporting: Track compliance rates and trends over time.

- Technology: Use tools to manage data and spot problems early.

These elements work together to create a robust compliance system. They help businesses stay on top of changing rules and supplier performance.

Supplier Compliance Framework

A supplier compliance framework sets rules and processes for working with vendors. It helps companies manage risks and ensure suppliers follow laws and standards. This framework is key for smooth business operations and avoiding issues.

Establishing Standards

Companies need clear standards for their suppliers. These standards cover quality, safety, ethics, and legal requirements. Many firms use industry-specific guidelines to set their rules.

Key areas often include:

- Product quality specs

- Delivery timelines

- Environmental practices

- Labour laws compliance

- Data security measures

It's vital to make these standards easy to understand. Use simple language and give examples where needed. This helps suppliers know exactly what's expected of them.

Regular updates to these standards are crucial. Laws and best practices change often. Keeping standards current ensures ongoing compliance and reduces risks in the supply chain.

Implementation Strategies

Putting a compliance framework into action takes careful planning. Firms should start by sharing their standards clearly with all suppliers. Training sessions can help explain complex rules.

Some effective strategies include:

- Creating a supplier handbook

- Holding regular compliance workshops

- Using online learning tools for remote suppliers

It's important to phase in new rules gradually. This gives suppliers time to adapt without disrupting business. Companies should also offer support to help suppliers meet new standards.

Technology plays a big role in modern implementation. Vendor compliance management systems can track progress and flag issues early. These tools help both buyers and suppliers stay on top of compliance tasks.

Monitoring and Reporting

Ongoing checks are key to a strong compliance framework. Regular audits help spot problems before they grow. Companies should set up clear schedules for these checks.

Effective monitoring includes:

- On-site inspections

- Document reviews

- Performance data analysis

It's crucial to keep good records of all compliance activities. This helps track progress over time and proves due diligence if issues arise.

Reporting is equally important. Create clear, simple reports that show compliance levels across the supply chain. Share these reports with key stakeholders regularly. This keeps everyone informed and helps drive improvements.

Supplier compliance programs should be flexible. Review and update monitoring methods as needed. This ensures the framework stays effective as business needs change.

Performance and Risk Management

Effective supplier management involves closely tracking performance and addressing potential risks. Companies need robust systems to measure supplier output and identify issues before they become major problems.

Supplier Performance Metrics

Supplier performance management (SPM) is crucial for maintaining high-quality supply chains. Key metrics often include:

- On-time delivery rates

- Quality control pass rates

- Cost savings achieved

- Response times to inquiries

- Customer satisfaction scores

Companies should set clear benchmarks for each metric. Regular performance reviews help identify top performers and those needing improvement.

Automated scoring systems can streamline the evaluation process. These tools aggregate data from multiple sources to provide a comprehensive view of supplier performance.

Risk Identification and Assessment

Identifying and assessing supplier risks is vital for supply chain stability. Common risk categories include:

- Financial risks (e.g. bankruptcy, cash flow issues)

- Operational risks (e.g. production delays, quality control failures)

- Compliance risks (e.g. regulatory violations, ethical breaches)

- ESG risks (environmental, social, and governance concerns)

- Cyber risks (data breaches, IT system failures)

Risk assessment tools use data analytics to score suppliers based on various factors. These may include financial health indicators, news sentiment analysis, and geographical risk factors.

Regular risk audits help companies stay ahead of potential issues. Suppliers in high-risk categories may require more frequent monitoring.

Risk Mitigation Strategies

Once risks are identified, companies must take action to reduce their impact. Effective risk mitigation strategies include:

- Diversifying the supplier base to reduce dependence on single sources

- Implementing contingency plans for supply chain disruptions

- Requiring suppliers to maintain insurance or financial reserves

- Conducting regular compliance audits and site visits

- Providing training and support to help suppliers improve their processes

Companies should also consider using AI-driven insights for proactive risk management. These tools can predict potential issues before they occur, allowing for early intervention.

Establishing clear communication channels with suppliers is crucial. This enables quick responses to emerging risks and fosters a collaborative approach to problem-solving.

Sustainability and Ethical Considerations

Companies now use analytics to track supplier practices around sustainability and ethics. This helps ensure responsible sourcing and reduces risks in the supply chain.

Environmental Sustainability

Supply chain analytics allow firms to measure suppliers' environmental impact. Key metrics include carbon emissions, water usage, and waste production.

Analytics tools can track:

• Energy efficiency

• Use of renewable resources

• Packaging materials

• Transport methods

With this data, companies can set targets for suppliers to improve. They can also find more eco-friendly alternatives when needed.

Some firms use blockchain to verify green claims. This creates a tamper-proof record of a product's journey. It helps prevent 'greenwashing' where suppliers exaggerate their efforts.

Supplier Diversity

Analytics help track spending with diverse suppliers. This includes businesses owned by women, minorities, veterans, and LGBTQ+ individuals.

Key metrics:

• % of spend with diverse suppliers

• Number of diverse suppliers

• Growth in diverse supplier relationships

Tools can flag opportunities to increase diversity. They may suggest new suppliers or areas to expand diverse spending.

Supplier diversity programmes boost innovation and reflect customer bases. They also support local economies and create jobs in underserved communities.

Ethical Sourcing

Analytics help firms spot risks of unethical practices in their supply chain. This includes forced labour, child labour, and unsafe working conditions.

Tools can track:

• Supplier audit results

• Worker complaints

• Local labour laws

• News and social media for red flags

Advanced analytics can predict high-risk suppliers. This allows for targeted audits and corrective action.

Some firms use worker voice platforms. These let employees report issues via mobile apps. The data helps spot problems early.

Data-Driven Supplier Compliance

Analytics tools help businesses track supplier performance and risks. These systems use large amounts of data to spot issues early and make smart decisions.

Leveraging Predictive Analytics

Predictive analytics uses past data to forecast future events. It helps firms spot potential supplier problems before they happen. For example, it can flag a supplier that may miss deadlines based on past performance.

These tools look at many factors. They check quality records, delivery times, and financial health. Some even track news and social media about suppliers.

Predictive models get smarter over time. The more data they have, the better their forecasts become. This lets companies take action sooner to prevent issues.

Importance of Accurate Data Sources

Good data is key for supplier compliance checks. Companies need trustworthy info from many places. This could be internal records, public databases, or third-party reports.

Data-driven insights help with due diligence. They show a full picture of each supplier's risks and strengths. But wrong data can lead to bad choices.

Firms should check their data often. They need to make sure it's up-to-date and correct. Some use AI to clean and verify data automatically.

Having clear data also improves visibility. It helps everyone in the company see how suppliers are doing. This makes it easier to work together on fixing problems.

Technological Tools and Solutions

Modern technology offers powerful solutions for supplier compliance analytics. These tools enhance monitoring, automate processes, and provide deep insights through advanced analytics.

Compliance Management Software

Compliance management software is a key tool for supplier risk management. It centralises data and streamlines workflows. These platforms often include features like:

• Supplier onboarding and screening

• Document management

• Risk assessment tools

• Reporting and dashboards

Many solutions offer configurable risk engines. These allow firms to set custom risk thresholds based on their policies.

The software can flag high-risk suppliers automatically. This saves time and improves accuracy in compliance checks.

Automation in Monitoring

Automated monitoring tools boost operational efficiency. They continuously scan for changes in supplier status or risk factors.

Key benefits of automation include:

• Real-time alerts for compliance issues

• Reduced manual effort in data collection

• Consistent application of compliance rules

Some systems use artificial intelligence to detect patterns. This can help spot potential risks before they become problems.

Automation also supports better record-keeping. It creates audit trails of all compliance activities.

Advanced Analytics for Compliance

Advanced analytics tools provide deeper visibility into supplier compliance. They can process large amounts of data to uncover trends and risks.

These tools often use techniques like:

• Predictive modelling

• Network analysis

• Natural language processing

Analytics can help identify hidden connections between suppliers. This is useful for uncovering conflicts of interest or fraud risks.

Some platforms offer visual analytics. These make complex data easier to understand and act upon.

Strengthening Supplier Relationships

Strong supplier relationships are vital for business success. They foster trust, improve efficiency, and lead to better outcomes for both parties. Let's explore key strategies to enhance these partnerships.

Strategic Sourcing

Strategic sourcing is a cornerstone of effective supplier management. It involves selecting suppliers based on more than just price. Companies must consider quality, reliability, and long-term value.

A well-planned approach helps firms find the best suppliers. It often includes:

• Thorough market research

• Detailed supplier evaluations

• Risk assessments

By using data-driven methods, businesses can make smarter choices. They can identify suppliers who align with their goals and values.

Strategic sourcing also means looking at the big picture. It's about building a network of trusted partners, not just filling immediate needs.

Collaborative Partnerships

Building strong supplier relationships goes beyond simple transactions. It's about creating true partnerships. This means working together to solve problems and achieve shared goals.

Open communication is key. Regular meetings and check-ins help keep everyone on the same page. Sharing information about future plans and challenges can lead to better solutions.

Joint projects can strengthen bonds. These might include:

• Product development initiatives

• Process improvement efforts

• Sustainability programmes

Trust is crucial in these partnerships. Both sides must be honest and follow through on commitments. When issues arise, a collaborative approach to problem-solving often yields the best results.

Continuous Improvement and Feedback

Ongoing assessment and feedback are vital for supplier relationship growth. Regular performance reviews help identify areas for improvement. They also highlight successes to build upon.

Effective feedback should be:

• Clear and specific

• Timely

• Constructive

It's not just about pointing out problems. Good feedback also recognises achievements and offers suggestions for growth.

Data analytics play a big role here. They can reveal trends and patterns that might otherwise go unnoticed. This information can guide improvement efforts and inform strategic decisions.

Suppliers should also have a chance to give feedback. Their insights can help companies refine their processes and become better partners themselves.

Regulatory and Trade Compliance

Supplier compliance analytics play a crucial role in navigating the complex landscape of regulations and trade requirements. Firms must adapt to ever-changing rules while managing risks across their global supply chains.

Adhering to Local and Global Regulations

Companies face a maze of regulations that vary by country and industry. Building a resilient supply chain requires robust compliance measures. Firms must track and follow rules on:

• Product safety standards

• Environmental protections

• Labour laws

• Data privacy requirements

Analytics tools help firms monitor supplier compliance with these rules. They can flag potential issues before they become major problems. For example, a system might alert when a supplier's certifications are about to expire.

Regulatory compliance isn't just about avoiding fines. It's also key to maintaining a good reputation and customer trust.

Managing Trade Compliance

Trade compliance involves following laws that govern the import and export of goods. This includes:

• Proper classification of goods

• Accurate customs declarations

• Adherence to trade agreements

• Screening for restricted parties

Global trade compliance solutions help firms stay up-to-date on foreign trade regulations. These tools can automate many aspects of trade compliance, reducing errors and saving time.

Analytics can spot patterns that might indicate fraud or other risks. For instance, they can identify unusual shipping routes or frequent changes to product descriptions. This helps protect the integrity of a firm's trade programme.

Vendor Management and Due Diligence

Effective vendor management and thorough due diligence are crucial for minimising risks and ensuring successful supplier relationships. These processes involve assessing vendor capabilities and implementing rigorous evaluation procedures.

Evaluating Vendor Capabilities

Vendor capability assessment is a key step in supplier risk management. It involves analysing a vendor's financial stability, operational capacity, and technical expertise. Companies can use data and analytical insights to improve supplier performance and lower costs.

A comprehensive evaluation should include:

- Financial health checks

- Operational capacity assessment

- Technical expertise review

- Compliance with industry standards

Firms should regularly monitor vendor performance using key performance indicators (KPIs). This helps identify potential issues early and allows for timely corrective actions.

Due Diligence Processes

Due diligence is a critical aspect of vendor management. It involves a detailed investigation of a potential supplier before entering into a business relationship. Vendor due diligence adopts a buyer's perspective, enabling companies to understand the value of a potential partnership.

Key elements of the due diligence process include:

- Background checks

- Financial analysis

- Legal and regulatory compliance review

- Operational capability assessment

Companies should use robust internal processes and analytics to identify and prioritise vulnerabilities. This approach helps enhance sourcing, procurement, and logistical processes while anticipating potential disruptions.

Implementing a comprehensive due diligence solution can streamline the process, especially when dealing with high volumes or complex checks. Such tools can significantly improve efficiency and accuracy in vendor evaluation.

Building Resilience in the Supply Chain

Supply chains face various risks that can disrupt operations. Companies need to identify weak points and create plans to handle problems. This helps keep the supply chain running smoothly even when issues come up.

Assessing Supply Chain Vulnerabilities

To build a resilient supply chain, firms must first spot potential weak areas. This means looking at each step, from getting raw materials to delivering finished goods. Common risks include natural disasters, supplier failures, and transport delays.

Companies can use data analytics to find weak spots in their supply chains. They should check which suppliers are critical and if there are backup options. It's also key to look at inventory levels and see if they can handle sudden changes in demand.

Regular risk assessments help catch new problems early. Firms should create a risk scorecard for each part of the supply chain. This makes it easier to track issues over time and take action quickly.

Developing a Resilient Strategy

Once risks are known, companies can make plans to deal with them. A good strategy has several parts:

- Diversify suppliers

- Build safety stock

- Create flexible transport options

- Improve information sharing

Having multiple suppliers for key items reduces the impact if one fails. Keeping extra stock can help during short-term disruptions. Flexible shipping methods allow quick changes if one route is blocked.

Better communication with suppliers and customers is crucial. This helps everyone respond faster to problems. Many firms use technology to track shipments and inventory in real-time.

Training staff to handle crises is also important. Regular drills can test how well plans work in practice. Companies should update their strategies as new risks appear.

Frequently Asked Questions

Supplier compliance analytics involves key components, data applications, and measurement techniques. Proper training and tools enhance procurement operations and supply chain management.

What are the key components of a supplier compliance checklist?

A supplier compliance checklist typically includes regulatory requirements, quality standards, and performance metrics. It may cover areas like health and safety, environmental regulations, and ethical practices.

The checklist should also address financial stability and risk assessment. Regular audits and reviews are essential to maintain compliance.

In what ways are data analytics applied within procurement operations?

Data analytics in procurement helps identify cost-saving opportunities and streamline supplier evaluation processes. It can forecast demand, optimise inventory levels, and assess supplier performance.

Analytics tools can also detect fraud, analyse spend patterns, and improve contract management. This data-driven approach leads to more informed decision-making.

How do procurement analytics tools enhance supplier compliance?

Procurement analytics tools automate compliance monitoring and provide real-time insights into supplier performance. They can flag potential risks and non-compliance issues before they escalate.

These tools often include dashboards for easy tracking of compliance metrics. They can also generate reports for stakeholders and regulatory bodies.

What training is necessary to understand supplier compliance analytics effectively?

Training should cover data analysis techniques, procurement software usage, and regulatory requirements. Understanding statistical methods and data visualisation is crucial.

Courses in supply chain management and risk assessment are beneficial. Hands-on experience with analytics platforms is also essential for proficiency.

How do you accurately measure a supplier's compliance rate?

To measure supplier compliance, establish clear performance indicators and evaluation criteria. Regular audits and assessments are key to gathering accurate data.

Use a scoring system based on predefined compliance criteria. Track improvements over time and compare against industry benchmarks for context.

Can you provide examples that illustrate the impact of procurement analytics on supply chain management?

A manufacturing company used analytics to identify supplier quality issues, reducing defect rates by 15%. This led to improved product quality and customer satisfaction.

A retail chain applied procurement analytics to optimise inventory levels, reducing stockouts by 20% and improving cash flow. This resulted in better supplier relationships and increased sales.