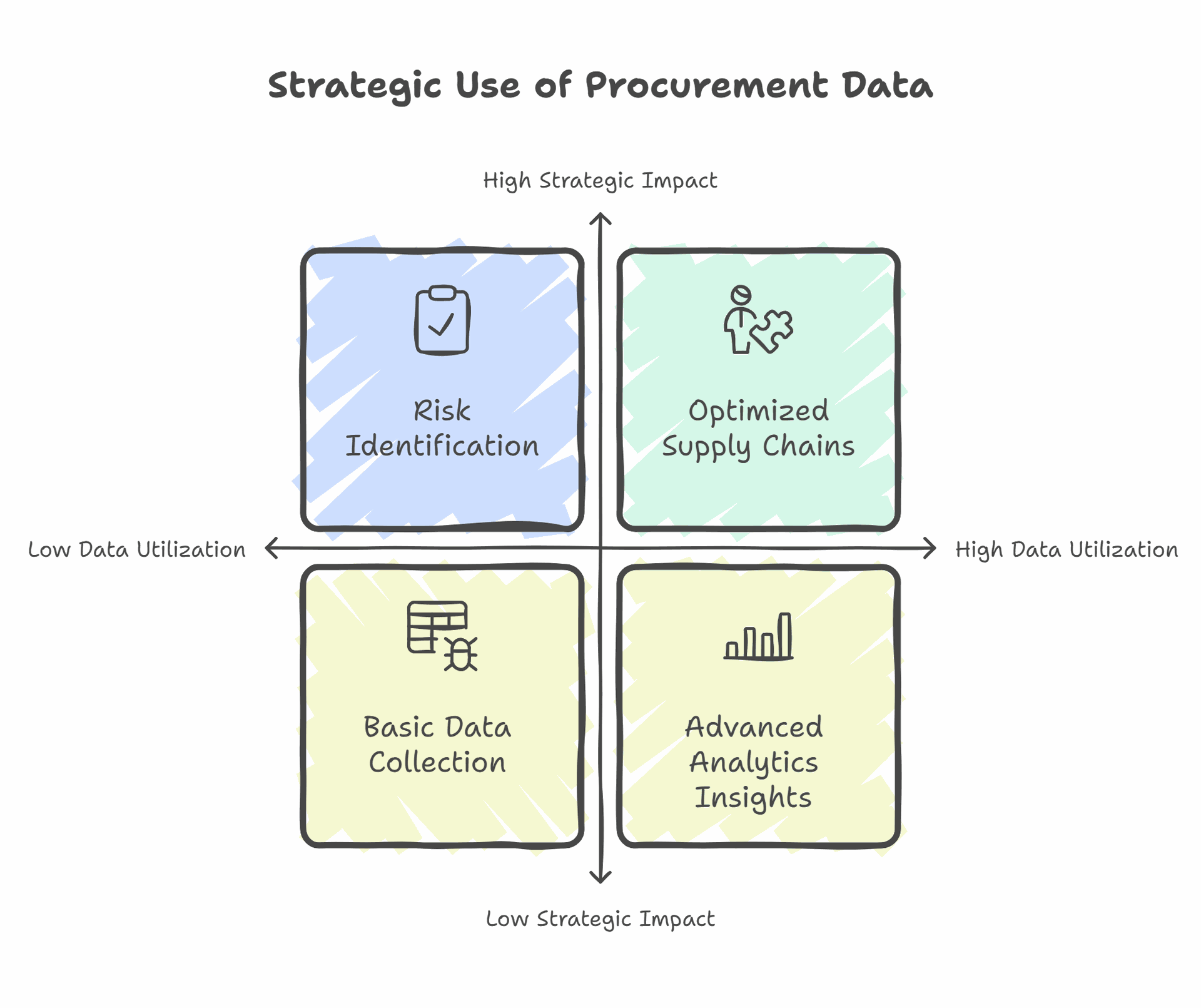

Procurement data is a goldmine for investment risk management. Companies can use this information to make smarter decisions and protect their investments. By analysing procurement data, organisations can identify potential risks, forecast market trends, and optimise their supply chains.

Advanced analytics in procurement can uncover valuable insights. These insights help with negotiations, vendor management, and yearly purchasing strategies. Companies that harness this data gain a competitive edge in the market.

Effective use of procurement data also enhances risk management. It provides a clearer picture of supplier health, project progress, and key performance indicators. This visibility allows businesses to reduce risks and make more informed investment choices.

Key Takeaways

- Procurement data analysis helps identify risks and optimise supply chains

- Advanced analytics in procurement uncover insights for better decision-making

- Effective use of procurement data enhances risk management and investment choices

Understanding Procurement and Its Role in Business

Procurement plays a vital role in business operations. It involves acquiring goods and services needed for an organisation to function effectively. Proper procurement practices help companies save money, manage risks, and build strong supplier relationships.

Fundamentals of Procurement Process

The procurement process involves several key steps:

- Identifying needs

- Sourcing suppliers

- Evaluating bids

- Negotiating contracts

- Placing orders

- Managing deliveries

- Reviewing performance

Effective procurement ensures that businesses get the right products at the right price and time. It also helps minimise risks associated with purchases.

Companies use various tools to streamline procurement. These may include:

- E-procurement systems

- Spend analysis software

- Contract management platforms

These tools help make procurement more efficient and data-driven.

Key Procurement Teams and Their Functions

Procurement teams handle different aspects of the buying process:

- Strategic sourcing: Finds long-term suppliers and negotiates contracts

- Category management: Oversees specific product or service categories

- Supplier relationship management: Maintains vendor partnerships

- Procurement operations: Handles day-to-day purchasing activities

Big data analytics is becoming crucial for procurement teams. It helps them make better decisions about suppliers, costs, and risks.

Procurement professionals need skills in negotiation, data analysis, and relationship building. They must also understand market trends and supply chain dynamics.

Importance of Supplier Relationships

Good supplier relationships are crucial for successful procurement. They can lead to:

- Better pricing

- Higher quality products

- More reliable deliveries

- Increased innovation

To build strong supplier relationships, companies should:

- Communicate clearly and often

- Pay on time

- Share forecasts and plans

- Offer feedback and performance reviews

Supplier risk management is a key part of procurement. It involves assessing and monitoring suppliers to prevent disruptions.

Companies may use scorecards to track supplier performance. This helps identify areas for improvement and recognise top performers.

Risk Management in Procurement

Effective risk management is crucial for successful procurement. It helps organisations identify, assess, and mitigate potential issues that could disrupt operations or increase costs.

Types of Procurement Risks

Procurement faces various risks that can impact an organisation's bottom line. Common procurement risks include:

• Supply chain disruptions • Quality issues • Price fluctuations • Supplier financial instability • Compliance violations • Cyber security threats

Each risk type requires specific strategies for mitigation. For example, supply chain disruptions may be addressed through diversifying suppliers, while quality issues might necessitate stricter inspection procedures.

The Necessity of Risk Assessment

Risk assessment is a critical step in procurement risk management. It involves:

- Identifying potential risks

- Analysing their likelihood and impact

- Prioritising risks based on severity

Regular risk assessments help organisations stay ahead of potential issues. They enable procurement teams to allocate resources efficiently and focus on the most critical areas of concern.

Data-driven approaches can enhance risk assessment accuracy. Advanced analytics and AI can process vast amounts of data to identify patterns and predict potential risks.

Developing a Risk Management Programme

A comprehensive risk management programme is essential for effective procurement. Key components include:

• Clear risk management policies and procedures • Defined roles and responsibilities • Regular risk assessments and monitoring • Mitigation strategies for identified risks • Continuous improvement processes

Robust data and information sources are crucial for driving assessments and quantifications. These may include supplier ratings, geographic risk assessments, and industry risk ratings.

Implementing technology solutions can streamline risk management activities. These tools can automate data collection, analysis, and reporting, making the process more efficient and effective.

Influence of Technology on Procurement

Technology is reshaping procurement practices, enabling better risk management and decision-making. Data analytics, AI, and machine learning are driving major advances in how organisations handle procurement.

Role of Data Analytics in Risk Management

Data-driven risk management is transforming procurement. Advanced analytics tools help firms spot potential issues early. These tools sift through vast amounts of data to identify patterns and anomalies.

With data analytics, procurement teams can:

• Assess supplier performance more accurately • Predict potential supply chain disruptions • Identify cost-saving opportunities

Real-time data analysis allows for quicker responses to changing market conditions. This agility is crucial in today's fast-paced business environment.

Data visualisation techniques make complex information easier to understand. This helps procurement professionals make more informed decisions about risk.

Impact of AI and Machine Learning

AI and machine learning are powerful tools for procurement risk management. These technologies can process and analyse data at speeds impossible for humans.

AI-powered systems can:

• Automate routine procurement tasks • Provide predictive insights on supplier behaviour • Optimise inventory levels to reduce risk

Machine learning algorithms improve over time, becoming more accurate in their predictions. This leads to better risk assessment and mitigation strategies.

AI can also help with supplier selection by analysing multiple factors simultaneously. This reduces the risk of choosing unreliable suppliers.

Procurement Technology Advancements

Modern procurement technology is streamlining processes and enhancing risk management. Cloud-based platforms offer real-time visibility into the entire procurement cycle.

Key advancements include:

- E-procurement systems for easier supplier management

- Blockchain for improved traceability and transparency

- Internet of Things (IoT) devices for supply chain monitoring

These technologies provide better control over procurement processes. They also generate valuable data for risk analysis.

Mobile apps allow procurement professionals to manage operations on the go. This increases responsiveness to potential risks.

Integrated systems connect procurement with other business functions. This holistic approach improves overall risk management strategies.

Enhancing Investment Decisions with Procurement Data

Procurement data offers valuable insights for investment risk management. It helps analyse supplier performance, assess financial stability, and reduce losses through strategic sourcing.

Analysing Supplier Performance

Supplier performance data is crucial for evaluating investment risks. It provides a clear picture of a supplier's reliability and quality.

Key performance indicators (KPIs) to monitor include:

- On-time delivery rates

- Quality control metrics

- Responsiveness to issues

These metrics help identify potential supply chain disruptions. They also reveal which suppliers consistently meet expectations.

Tracking performance trends over time is essential. It shows whether a supplier is improving or declining. This information guides decisions on maintaining or changing suppliers.

Assessing Financial Stability through Procurement Data

Procurement data offers insights into a company's financial health. It reveals spending patterns and supplier relationships.

Key areas to examine include:

- Payment terms and history

- Contract values and durations

- Supplier diversity

Evaluating suppliers' financial health is crucial. It helps predict potential supply chain disruptions due to financial instability.

Analysing procurement data can reveal:

- Cash flow management effectiveness

- Negotiation power with suppliers

- Potential cost-saving opportunities

These insights help assess a company's financial stability and growth potential.

Reducing Financial Losses with Strategic Sourcing

Strategic sourcing using procurement data can significantly reduce financial losses. It involves analysing spending patterns and supplier performance to make informed decisions.

Benefits of data-driven strategic sourcing:

- Identifies cost-saving opportunities

- Mitigates supply chain risks

- Improves supplier negotiations

Risk management in procurement now includes a broader set of activities. It goes beyond basic supplier due diligence.

Data analysis helps in:

- Identifying alternative suppliers

- Negotiating better contract terms

- Forecasting future spending needs

By leveraging procurement data, companies can make more informed investment decisions and reduce financial risks.

Legal and Regulatory Compliance

Proper management of legal and regulatory aspects is crucial for effective procurement data use in investment risk management. This involves understanding contractual obligations, staying abreast of regulatory changes, and safeguarding data security and privacy.

Understanding Contractual Obligations

Contracts form the backbone of procurement relationships. They outline the terms, conditions, and responsibilities of all parties involved. It's vital to review contracts thoroughly to identify potential risks and compliance requirements.

Key aspects to consider include:

- Payment terms

- Delivery schedules

- Quality standards

- Termination clauses

- Liability limits

Regular contract audits help ensure ongoing compliance. These reviews can uncover hidden risks or opportunities for improvement. It's wise to involve legal experts in complex contract evaluations.

Monitoring Regulatory Changes

The regulatory landscape for procurement and investment is ever-changing. Staying current with these changes is essential for risk management and compliance.

Steps to stay informed include:

- Subscribing to regulatory updates

- Attending industry conferences

- Joining professional associations

Organisations should establish a system to track and analyse relevant regulations. This might involve creating a regulatory change log or using specialised software.

It's important to assess the impact of new regulations on existing processes and contracts. This allows for timely adjustments to maintain compliance.

Ensuring Data Security and Privacy

Data security and privacy are paramount in procurement and investment activities. Organisations must protect sensitive information from unauthorised access or breaches.

Key measures include:

- Implementing robust cybersecurity protocols

- Encrypting sensitive data

- Conducting regular security audits

- Training staff on data handling best practices

Compliance with data protection regulations like GDPR is crucial. This involves obtaining proper consent for data collection and use, and ensuring data portability and the right to erasure.

It's advisable to appoint a data protection officer to oversee compliance efforts. Regular risk assessments can help identify vulnerabilities in data handling processes.

Responding to Supply Chain Disruptions

Supply chain disruptions can have significant impacts on businesses. Effective strategies to address these challenges include managing market volatility, preparing for natural disasters, and building resilience into supply chain operations.

Mitigating Risks From Market Volatility

Market volatility can cause major issues in supply chains. To address this, companies should diversify their supplier base. This means not relying on just one or two suppliers for key materials.

Real-time data on delays and shipment deliveries is crucial. It helps firms spot potential problems early.

Hedging strategies can also help manage price fluctuations. For example, companies might use futures contracts to lock in prices for commodities.

Building stronger relationships with suppliers is key. This can lead to better communication and more flexible terms during volatile periods.

Planning for Natural Disasters and Environmental Changes

Natural disasters and environmental shifts can severely disrupt supply chains. Companies need robust contingency plans to cope with these events.

Climate risk analysis should be part of supply chain planning. This helps identify vulnerable areas in the supply network.

Firms should map out alternative transportation routes. This ensures goods can still move if usual paths are blocked.

Investing in local suppliers can reduce exposure to global disruptions. It also helps cut transportation times and costs.

Regular drills and simulations can help teams prepare for real emergencies. These exercises can reveal weaknesses in current plans.

Implementing Resilience and Continuity in Supply Chain Management

Building resilience into supply chains is crucial for long-term success. This involves creating flexible systems that can adapt to disruptions.

Increasing inventory of key components is one strategy. While this ties up capital, it provides a buffer against short-term supply issues.

Using technology like AI and blockchain can improve supply chain visibility. This allows for quicker responses to potential disruptions.

Cross-training employees helps maintain operations if key staff are unavailable. It also improves overall understanding of the supply chain.

Regular risk assessments are vital. These should cover all aspects of the supply chain, from raw materials to final delivery.

Sustainability and Ethical Considerations

Responsible procurement practices are crucial for managing investment risks and promoting long-term value. Companies can reduce environmental impact, uphold ethical standards, and create positive social change through thoughtful purchasing decisions.

Pursuing Carbon Reduction in Procurement

Sustainable procurement plays a vital role in lowering carbon emissions. Firms can set specific targets for suppliers to cut greenhouse gases. This may include:

• Requiring eco-friendly packaging • Prioritising local suppliers to reduce transport emissions • Incentivising renewable energy use in production

Procurement teams should track and report on carbon metrics. They can use data analytics to identify high-emission areas in the supply chain. By addressing these, companies can make significant strides in reducing their carbon footprint.

Promoting Sustainable Sourcing

Sustainable sourcing focuses on environmentally and socially responsible practices. Key strategies include:

- Circular economy principles: Prioritise recycled materials and products designed for reuse

- Biodiversity protection: Choose suppliers that avoid deforestation and protect ecosystems

- Water conservation: Select vendors with water-efficient production methods

Sustainability-related risk management becomes more challenging with lower-tier suppliers. To address this, companies should:

• Implement supplier training programmes • Conduct regular audits • Use blockchain technology for supply chain transparency

Assessing Ethical Impact of Procurement Choices

Ethical procurement considers the social consequences of purchasing decisions. Key areas to assess include:

- Labour practices: Ensure fair wages and safe working conditions

- Human rights: Verify suppliers don't use child labour or forced labour

- Community impact: Choose vendors that support local communities

Procurement teams should develop a scoring system for ethical considerations. This can be integrated into supplier selection processes. Regular supplier assessments and stakeholder engagement are essential for maintaining ethical standards.

By prioritising sustainability and ethics in procurement, companies can mitigate risks and build resilience. This approach not only protects reputation but can also lead to increased profits through improved efficiency and stakeholder trust.

Strategic Procurement for Competitive Advantage

Strategic procurement goes beyond cost-cutting. It aims to create value and gain an edge in the market. Smart procurement strategies can help firms adapt to changes and drive innovation.

Utilising Procurement Strategy for Market Adaptation

Firms can use procurement to react quickly to market shifts. A flexible approach to sourcing helps firms stay agile. They can switch suppliers or materials as needed.

Data-driven decisions are key. Firms should track market trends and supplier performance. This lets them spot risks and chances early on.

Diversifying the supply base is smart. It reduces reliance on one source. Firms can also look for local suppliers to cut shipping costs and times.

Building strong ties with key suppliers is crucial. It ensures a steady supply of vital goods. These bonds can also lead to joint problem-solving.

Leveraging Supplier Innovation and Development

Suppliers can be a great source of new ideas. Smart firms tap into this resource. They set up systems to gather and test supplier suggestions.

Joint R&D projects with suppliers can lead to breakthroughs. Firms can share costs and risks. This approach often yields better results than working alone.

Supplier development programmes boost the whole supply chain. Firms can help suppliers improve their skills and processes. This leads to better quality and efficiency.

Regular supplier forums and workshops foster teamwork. They create a space to share best practices. These events can spark new ideas and solutions.

Importance of Performance and Compliance Management

Clear metrics are vital for tracking supplier performance. Firms should set and monitor key indicators. These might include quality, delivery times, and cost savings.

Regular audits help ensure compliance. Firms should check that suppliers follow all rules and standards. This protects the firm's reputation and reduces risks.

A fair system of rewards and penalties drives good behaviour. Suppliers who excel should get more business. Those who fall short need clear plans to improve.

Technology can streamline compliance checks. Automated systems can flag issues quickly. This allows for faster responses to problems.

Final Considerations in Procurement Risk Management

Effective risk management in procurement requires a multifaceted approach. Key factors include thorough due diligence, leveraging technology, and enhancing internal capabilities.

Conducting Effective Due Diligence

Due diligence is crucial for risk management in procurement. It involves gathering and analysing information about potential suppliers, contracts, and market conditions. Procurement teams should develop a checklist for due diligence that covers financial stability, legal compliance, and operational capacity.

Regular supplier audits are essential. These audits help identify potential risks and ensure ongoing compliance. Organisations should also monitor industry trends and geopolitical factors that could impact supply chains.

It's important to document all due diligence activities. This documentation serves as a reference for future decision-making and demonstrates good governance practices.

Utilising Enterprise Resource Planning Systems

Enterprise Resource Planning (ERP) systems play a vital role in procurement risk management. These systems centralise data and provide real-time insights into procurement activities.

ERP systems can:

- Track supplier performance

- Monitor inventory levels

- Analyse spending patterns

- Generate risk reports

By integrating procurement data with other business functions, ERP systems enable better decision-making. They can flag potential issues before they become critical problems.

Organisations should invest in training staff to use ERP systems effectively. This ensures the full benefits of the technology are realised.

Improving Internal Processes and Skills Development

Strong internal processes are the backbone of effective procurement risk management. Organisations should regularly review and update their procurement policies and procedures.

Key areas for improvement include:

- Risk assessment methodologies

- Supplier evaluation criteria

- Contract management practices

Skills development is equally important. Procurement teams need ongoing training in risk management techniques, data analysis, and emerging technologies.

Organisations should consider creating specialised roles focused on procurement risk management. These roles can lead efforts to identify, assess, and mitigate risks across the procurement function.

Cross-functional collaboration is crucial. Procurement teams should work closely with finance, legal, and operations departments to develop comprehensive risk management strategies.

Frequently Asked Questions

Procurement data plays a crucial role in investment risk management. Understanding key aspects of this relationship helps organisations make informed decisions and mitigate potential issues.

How can risk management be effectively integrated into procurement processes?

Risk management can be woven into procurement processes through several methods. Regular risk assessments help identify potential issues early on. Implementing robust supplier vetting procedures ensures reliable partners.

Clear communication channels between procurement and risk management teams facilitate quick responses to emerging threats. Continuous monitoring of supplier performance and market conditions allows for proactive risk mitigation.

What are the four principal sources of risk within procurement activities?

The four main sources of risk in procurement are supplier-related, market-related, operational, and reputational risks. Supplier risks include financial instability or quality issues. Market risks involve price fluctuations and supply shortages.

Operational risks encompass internal process failures or technology breakdowns. Reputational risks stem from ethical breaches or negative publicity associated with suppliers or procurement practices.

In what ways does the use of data enhance procurement practices?

Data usage improves procurement practices by enabling more informed decision-making. It allows for accurate spend analysis, helping identify cost-saving opportunities. Predictive analytics can forecast market trends and potential supply chain disruptions.

Performance metrics derived from data help evaluate supplier effectiveness. Real-time data insights enable quick responses to changing market conditions or supplier issues.

What is the interplay between procurement strategies and risk management?

Procurement strategies and risk management are closely intertwined. Effective risk management informs procurement strategies by identifying potential threats and opportunities. This allows for the development of contingency plans and alternative sourcing options.

Conversely, procurement strategies influence risk management by determining supplier selection criteria, contract terms, and supply chain structures. A balanced approach ensures both risk mitigation and strategic procurement goals are met.

How can operational risks in procurement be identified and mitigated?

Operational risks in procurement can be identified through process mapping and regular audits. Implementing robust data management systems helps track and analyse performance metrics, flagging potential issues.

Mitigation strategies include standardising processes, providing staff training, and implementing checks and balances. Automation of routine tasks can reduce human error. Establishing clear escalation procedures ensures quick responses to operational issues.

What legal and industry considerations impact the formulation of a sourcing risk management plan?

Legal considerations in sourcing risk management include compliance with trade regulations, data protection laws, and industry-specific standards. Contracts must be carefully drafted to address liability and dispute resolution.

Industry-specific factors such as supply chain complexity, technological advancements, and environmental regulations also shape risk management plans. Staying informed about industry trends and regulatory changes is crucial for effective risk management in procurement.